How often should transformer oil be tested?

Testing of Transformer Oil :

In order to determine the suitability of the oil, following tests should be carried out before using the insulating oil.

1. Flash point or Breakdown test.

2. Crackle test.

3. Sight test.

4. Acidity test.

1. Flash point or Breakdown test :-

This test is performed to check the dielectric strength of the transformer oil.

|

| Testing Equipment |

The test is performed in the oil testing set. The sample of oil is drawn from near the top and bottom of the transformer and tested in the oil testing set. A lower than 30KV dielectric strength of a 4 mm gap of electrodes would indicate presence of moisture in the oil. The actual testing is done as follows.

|

| Oil testing set |

- A-Main Switch.

- B- Main indicating lamp.

- F or H- Push button.

- H, T or G- Push button off.

- J- Voltmeter.

- O- Motor stop switch.

- R- Electrodes.

- 1- Bakelite disc.

- 2- Electrodes.

- 3- Handles.

- 4- Acrylic Cover.

- 5- Variac Knob.

The supply is switched on and voltage is raised gradually by the Variac, the stage comes when the final breakdown of the oil takes place and the circuit breaker is got tripped which disconnects the transformer from the main supply.

This value is noted down which must be 30 KV (r.m.s.) for 4 mm ± 0.02 gap and 20 KV (r.m.s.) for 2.5 mm gap. The test is performed with two or three consecutive samples of oil turn by turn. With interval of one minute to allow the bubbles to escape. Average of all subsequent tests is considered as the breakdown voltage of oil sample.

2. Crackle Test :-

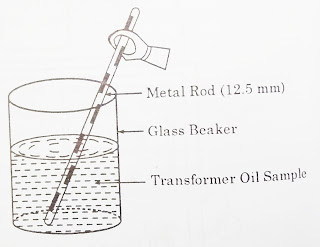

The test is performed to check the presence of moisture in the insulating oil . To perform this test, a sample oil of 250 ml is taken in a beaker. One iron rod of 12.5 mm is made red hot and dipped in this sample of oil.

|

| Crackle Test |

If there is any hissing sound coming through the oil in the breaker, it indicates the presence of moisture contents in the oil which will be considered not suitable for the use.

3. Sight Test :-

As per ISI 1896 - 1967 this test can be performed by taking water in the beaker and bent tube is filled with sample oil. The level in the tube of the oil should not be less than 35 mm by level of water in the beaker.

|

| Sight Test |

Close the end of the tube and fix it on the stand by dipping into water. If the bubbles appear at the jet, then it will indicate the presence of moisture contents in the oil. This test is rarely used because the oil testing set is not easily available in the laboratory.

4. Acidity Test :-

It is defined as the measure of free organic and inorganic present together in the oil. It is expressed in terms of the number of milli-grams of potassium hydroxide required to neutralize the total free acid in one gram of material.

Tendency of the oil to develop acidity requires to be carefully watched. If the acidity exceeds prescribed limit metal surface above oil level are likely to be corroded on account of acidic vapours.

Please do not enter any spam link in the comment box. ConversionConversion EmoticonEmoticon