What is Hysteresis motor ?

A hysteresis motor is basically a synchronous motor with uniform airgap and without d.c. excitation. This motor may operate from single-phase or 3-phase supply.

In a hysteresis motor torque is produced due to hysteresis and eddy current induced in the rotor by the action of the rotating flux of the stator winding.

In a hysteresis motor torque is produced due to hysteresis and eddy current induced in the rotor by the action of the rotating flux of the stator winding.

Construction of Hysteresis motor :

The hysteresis motor is divided into two parts according to the construction.

(i) Stator.

Stator construction

The stator of a hysteresis motor is similar to that of an induction motor with the basic requirement that it produces a rotating magnetic field. Thus the stator of the motor can be connected to either single-phase supply or 3-phase supply. We know that 3-phase motors produce a more, the stator winding is of permanent split-capacitor type, the capacitor should be used with an auxiliary winding in order to produce as uniform field as possible.

Rotor construction

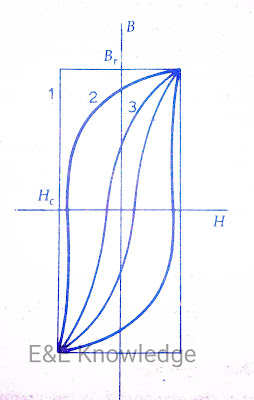

The rotor of a hysteresis motor. It consists of core of aluminium or some other nonmagnetic material which carries a layer of special magnetic material. The outer layer has a number of thin rings to form the laminated rotor. In smaller motors a solid ring may be used. Thus, the rotor of a hysteresis motor is a smooth cylinder and it does not carry any winding (no rotor bars). The ring is made of special magnetic material such as magnetically hard chrome or cobalt steel having very large hysteresis loop as shown in fig below

|

| Various hysteresis loops for different materials |

Working principle of Hysteresis Motor:

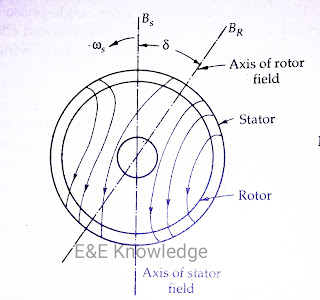

When a 3-phase supply or a single phase is applied to the stator, a rotating magnetic field is produced. This rotating magnetic field magnetized the rotor ring and induces poles within it. A uniform cross-section rotor inherently will match the number of stator poles. The induction rotor flux lags behind the rotating stator flux because of the hysteresis loss in the rotor. The the δ between the stator magnetic field Bs and the rotor magnetic field Br is responsible for the production of torque.

The angle δ depends only on the shape of the hysteresis loop. It doesn't depend upon the frequency. For this reason, a magnetic material having a wide Hysteresis loop should be used. Thus the coercive force Hc and the residual flux density Br of the magnetic material should be large. An ideal material would have a rectangular hysteresis loop 1 as shown by loop in fig below:

Ordinary steels are not suitable for a hysteresis motor since their hysteresis loops resemble loop 3 . Cobalt-vanadium type materials are used in hysteresis motors. They have the hysteresis loops according to loop 2 in fig . Such a loop approximates the ideal loop 1.

In addition, the stator magnetic field produces eddy currents in the rotor. These eddy currents produce their own magnetic field. Thus there is an additional torque on the rotor due to these eddy currents.

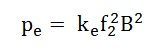

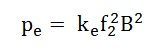

The eddy-current loss is given by

|

| Magnetic field in a hysteresis motor |

The angle δ depends only on the shape of the hysteresis loop. It doesn't depend upon the frequency. For this reason, a magnetic material having a wide Hysteresis loop should be used. Thus the coercive force Hc and the residual flux density Br of the magnetic material should be large. An ideal material would have a rectangular hysteresis loop 1 as shown by loop in fig below:

Ordinary steels are not suitable for a hysteresis motor since their hysteresis loops resemble loop 3 . Cobalt-vanadium type materials are used in hysteresis motors. They have the hysteresis loops according to loop 2 in fig . Such a loop approximates the ideal loop 1.

In addition, the stator magnetic field produces eddy currents in the rotor. These eddy currents produce their own magnetic field. Thus there is an additional torque on the rotor due to these eddy currents.

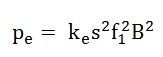

The eddy-current loss is given by

Where,

- ke is a constant

- f2 is the eddy current frequency

- B is the flux density

- But

Where s is the slip and f1 is the stator frequency.

Where s is the slip and f1 is the stator frequency. - Also, the torque is given by

-

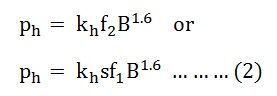

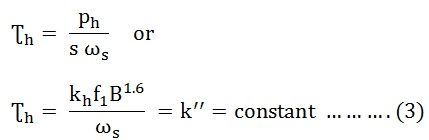

Torque due to hysteresis loss The hysteresis loss is given by :The Torque due to hysteresis is given a

- It is seen from the equation that torque is proportional to the slip. Therefore Ʈe decreases as the rotor speed increases. When the motor reaches synchronous speed, the slip becomes zero and the torque becomes zero. The stator current falls off and the rotor acts like a permanent magnet and the machine runs as a permanent magnet type motor. It is to be noted that the torque aids in the starting of the motor.

- The electromagnetic torque developed by a hysteresis motor due to hysteresis is given by equations. This component of torque remains constant at all rotor speeds until the breakdown torque. Since torque is zero at synchronous speed the only

- torque at synchronous speed is the torque. Thus at synchronous speed the induced torque in the motor is proportional to the angle δ between the stator and rotor magnetic fields upto a maximum angle set by the hysteresis in the motor.

Torque-speed Characteristics :

- An ideal torque-speed curve for the hysteresis motor is shown by curve 1 in fig below

- The torque-speed characteristics of a particular hysteresis motor is shown by curve 2 in fig below

The departure from the ideal characteristics 1 is due to presence of harmonics in the rotating field and other irregularities. The torque-speed characteristics of a hysteresis motor is quite different from that of an induction motor.

The torque developed by an induction motor becomes zero at synchronous speed, while in an ideal hysteresis motor it is constant at all speeds including synchronous speed. Thus it is seen from the characteristics that locked rotor, starting and pullout torque are all equal. This is a valuable property in that such a motor can pull into synchronism at high inertia loads.

Application of Hysteresis Motor :

The hysteresis motor has a very low noise level compared to single-phase induction motor. This is because it operates at one speed (synchronous speed) and it's rotor is smooth (unspotted) . With a permanent capacitor stator, the hysteresis motor is the smoothest running, quietest single-phase motor and therefore is preferred for quality sound reproduction equipment like record players tape recorder etc.

Please do not enter any spam link in the comment box. ConversionConversion EmoticonEmoticon