Which type of rotor are used in three phase induction motor ? and construction of induction motor

Three phase Induction Motor Construction :-

Three-Phase induction motor is the most popular type of a.c. motor. It is vary commonly used for industrial drives since it is cheap, robust, efficient and reliable.

It has good speed regulation and high starting torque. It requires little maintenance. It has a equitable overload capacity.

Construction:

3 phase induction motor is essentially consists of two parts —

(1) Stator and

(2) Rotor

The stator is the stationary part and rotor is the rotating part.

Stator :

The stator is build up of high grade sit still aluminium to reduce eddy-current losses.

The aluminium are slotted on the inner periphery and are insulated from each other.

These laminations are supported in a stator frame of cast iron or fabricated steel plate. The insulated stator conductor are placed in these slots. The stator conductor are connected to form a three phase winding. The phase winding may be either star or delta connected.

Which type of rotor are used in three phase induction motor ?

Rotor :

The rotor is also built up of thin laminations of the same material as stator.

The laminated cylindrical core is mounted directly on the shaft or a spider carried by the shaft.

These laminations are slotted on their outer periphery to receive the rotor conductors. These are two types of induction motor rotors.

- Squirrel cage rotor or simply cage rotor.

- Phase wound or wound rotor. Motors using this type of rotor are also called slip-ring motors.

Cage rotor :

It consists of a cylindrical laminated core with slots nearly parallel to the shaft axis, or skewed.

Because the main purpose of skewing is to reduce the magnetic locking between the stator and the rotor. During locking, the rotor and stator teeth attract each other due to magnetic action

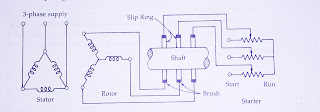

Wound rotor or slip ring rotor :

The wound rotor consists of a slotted armature. Insulated conductors are put in the slots and connected to form a three phase double layer distributed winding similar to the stator winding.

The rotor winding are connected in star. The open end of the star circuit are brought outside the rotor and connected to three insulated slip rings.

The slip rings are mounted on the shaft with brushes resting on them. The brushes are connected to three variable resistors connected in star. The purpose of slip rings and brushes is to provide a means for connecting external guests resistors in the rotor circuit.

The resistors enable the variation of each rotor phase resistance to serve two purposes :

- To increase the starting torque.

- To decrease the starting current from the supply current.

- To control the speed of the motor.

Please do not enter any spam link in the comment box. ConversionConversion EmoticonEmoticon