How to start a Induction Motor ?

OR

Starting of Induction Motor

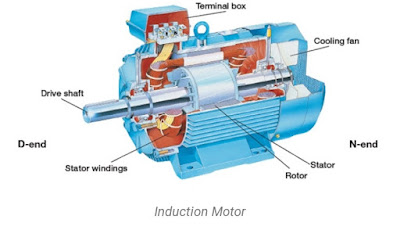

A three phase Induction Motor is Self Starting. When the supply is connected to the stator of a three-phase induction motor, a rotating magnetic field is produced, and the rotor starts rotating and the induction motor starts. At the time of starting, the motor slip is unity, and the starting current is very large.

The purpose of a starter is not to just start the motor, but it performs the two main functions. They are as follows.

- To reduce the heavy starting current

- To provide overload and under voltage protection.

The three phase induction motor may be started by connecting the motor directly to the full voltage of the supply. The motor can also be started by applying a reduced voltage to the motor when the motor is started.

The torque of the induction motor is proportional to the square of the applied voltage.Thus, a greater torque is exerted by a motor when it is started on full voltage than when it is started on the reduced voltage.

There are three main methods of Starting of Cage Induction Motor. They are as follows.

Direct On Line Starter

- It is simple and cheap starter for a 3-phase induction motor.

- The contacts close against spring action.

- This method is normally limited to smaller cage induction motors, because starting current can be as high as eight times the full load current of the motor. Use of a double –cage rotor requires lower staring current( approximately four times) and use of quick acting A.V.R enables motors of 75 Kw and above to be started direct on line.

- An isolator is required to isolate the starter from the supply for maintenance.

- Protection must be provided for the motor. Some of the safety protections are over-current protection, under-voltage protection, short circuit protection, etc. Control circuit voltage is sometimes stepped down through an autotransformer.

Star Delta Starter

- A two-position switch (manual or automatic) is provided through a timing relay.

- Starting in star reduces the starting current.

- When the motor has accelerated up to speed and the current is reduced to its normal value, the starter is moved to run position with the windings now connected in delta.

- More complicated than the DOL starter, a motor with a star-delta starter may not produce sufficient torque to start against full load, so output is reduced in the start position. The motors are thus normally started under a light load condition.

- Switching causes a transient current which may have peak values in excess of those with DOL.

Auto Transformer Motor Starting

- Operated by a two position switch i.e. manually / automatically using a timer to change over from start to run position.

- In starting position supply is connected to stator windings through an auto-transformer which reduces applied voltage to 50, 60, and 70% of normal value depending on tapping used.

- Reduced voltage reduces current in motor windings with 50% tapping used motor current is halved and supply current will be half of the motor current. Thus starting current taken from supply will only be 25% of the taken by DOL starter.

- For an induction motor, torque T is developed by V2, thus on 50% tapping, torque at starting is only (0.5V)2 of the obtained by DOL starting. Hence 25% torque is produced.

- Starters used in lager industries, it is larger in size and expensive.

- Switching from start to run positions causing transient current, which can be greater in value than those obtained by DOL starting.

Please do not enter any spam link in the comment box. ConversionConversion EmoticonEmoticon